December 18, 2023 - (Taipei, Taiwan) Taiwan has been a powerhouse of manufacturing in the bicycle industry for many years, with its quality and precision of both bikes and parts being second to none.

The industry’s focus has now expanded to e-bikes and other environment-friendly initiatives, which has grown to include ESG (Environmental, Social, Governance) targets and other ways of reducing their impact. As a result recycling and the use of recycled materials have also become a top priority for most Taiwanese bicycle and parts companies.

Following our visit at Hyena and Tektro, the final two companies on our media tour, Taipei Cycle held a press conference to review the direction that their upcoming show will take in 2024, and their commitment to ESG.

Next year’s event will embrace the themes of Micromobility, Innovations and Start Ups, Green Action and Culture and Lifestyle.

Taiwan’s focus on e-bikes in recent years has seen the average unit price grow by 30% demonstrating the country’s leadership in this segment of the cycling industry.

“The Taiwanese industry is selling more e-bikes,” commented Simon Wang, CEO of TAITRA, who stressed the need for electrification in the bicycle industry as a way to increase micromobility in cities for faster and more efficient transportation.

Wang added that the 2024 edition of Taipei Cycle, taking place March 6-9 next year, has rebounded to pre-pandemic levels with 900 exhibitors representing 30 countries displaying their products. The fourth floor of Hall 2 will be dedicated to the display of e-bikes and related products, including a test track.

He also stressed the dedication of the industry to reduce its carbon footprint, stating that sustainability is a key part of their responsible business practices. The industry has made significant progress in sustainable manufacturing and the recycling of waste materials.

To highlight Taiwan’s ongoing environmental efforts, a mini trade show was on site at the press conference, with companies showcasing their green initiatives – check out our trade show coverage that follows our media tour report of the final two companies.

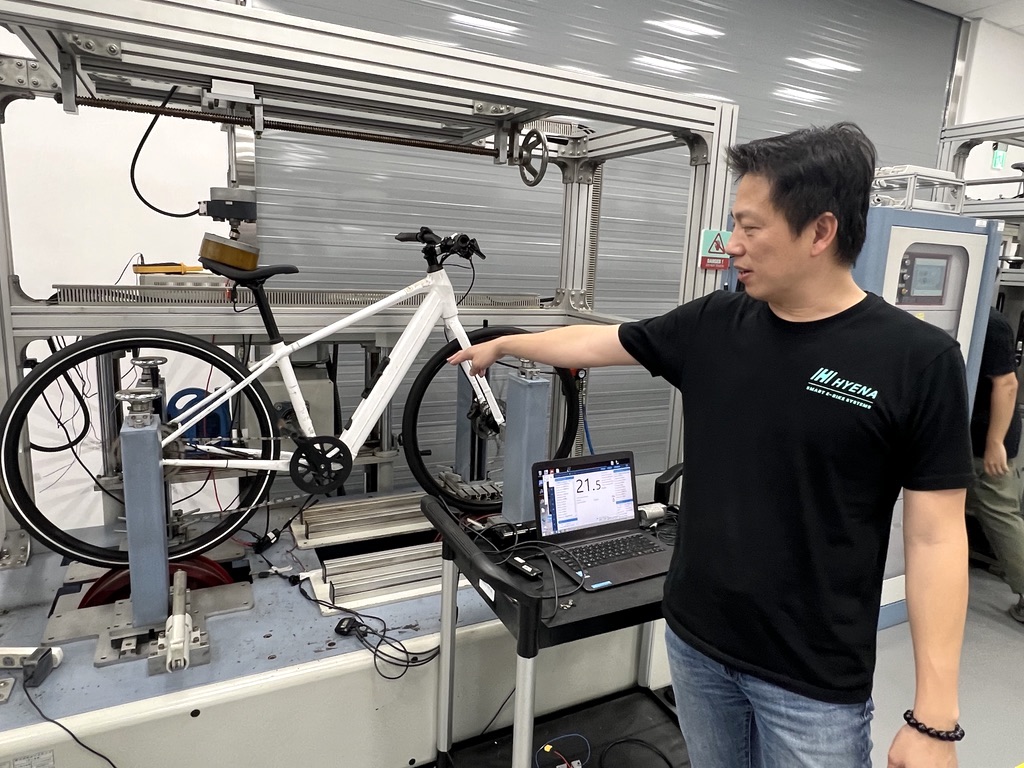

Hyena E-Bike Systems

Launched in 2013, Hyena E-Bike Systems celebrated its 10th anniversary this year. Started by CEO Charlie Chuang and partner Benno Wang, the duo brought considerable industry experience to the new company and unveiled their first e-bike hub motor prototypes in 2014.

After four years of refining their process, Hyena started producing kits for e-bikes in 2018, which included the software required to run the motor and battery harmoniously.

This approach is not common for companies making e-bike motors, and in fact, Hyena does not consider themselves a manufacturer but rather more of a design company. They create e-drive systems, outsource the manufacturing of the parts, and then take care of the final assembly of the motors.

They also execute intensive in-house testing on the final products to determine the e-bike’s range, the durability of their hub motors when starting and stopping on hills, as well as vibration testing. Battery packs are also designed in house to work with their software and motors.

Currently they produce 240,000 hub motor systems annually via two production lines. Hyena’s next big step is the launch of their new mid-drive motor weighing in at 2.4 kg.

This follows the recent introduction in June of their new E-Road Air, an ultra-lightweight rear hub drive system. The motor weighs a scant 1.3 kg and features 30Nm of torque on the hub axle.

The new E-Road Air is a great option for road bike manufacturers looking for the attributes of an e-drive system without adding much weight to their bicycles. Using a hi-resolution torque and cadence sensor, the new system can accurately measure a cyclist’s pedaling behaviour. This data is then processed through Hyena’s software and advanced bionic algorithm to provide a natural feel while supplementing the rider’s own power.

Working with some of the top cycling companies in the world such as Trek and Cannondale has helped Hyena gain some notoriety. “Trek is a big partner for us in terms of improvement. They push us to get better and have been an excellent customer for us,” commented Chuang.

During our visit we were able to test ride the new mid-drive motor which performed well and offered smooth and even acceleration, with excellent hill-climbing assistance.

Hyena’s innovative and lightweight systems will no doubt attract other mainstream players as e-bikes continue to surge in popularity worldwide.

Tektro Technology Group

Founded in 1986 Tektro has been a major supplier of bicycle parts and accessories with 90% of their sales going to original equipment manufacturers (OEM) in the cycling industry.

With over 1,500 employees, two factories in China and three in Taiwan, along with a research center in Taichung, they distribute their products in over 41 countries.

While Tektro focuses on mid- to entry-level bicycles for a large part of their business, they launched TRP in 2006 to cater to cycling’s higher-end bicycles, including the aftermarket.

In 2019 they launched a rear derailleur and shift lever set, and have recently unveiled a 12-speed mountain bike TRP drivetrain set to launch in 2023. They have their own patents on the rear derailleur, and have had to address 10,000 existing patents so as to not infringe on any.

The quality of the new drivetrain is impeccable and it is currently being used on the World Cup circuit. Their goal is to be the number two component brand worldwide, but their big focus is on disc brakes.

With over 140 CNC machines, Tektro is capable of ramping up production as needed. The CNC units are set up to machine a brake caliper in 30 seconds. Each brake lever is made in about the same amount of time and they produce 2-3 million sets per year. The forging is done in house and they manufacture their own brake pads as well.

All of the assembly is automated with custom machines installing the “O” rings and bolts, as well as cutting the hydraulic hoses.

Tektro also has a strong ESG framework with ISO programs implemented to measure and reduce their CO2 footprint, along with energy management.

They are also a founding member of the Bicycle Alliance for Sustainability (BAS), a group of companies that has pledged to reduce carbon emissions and has adopted ESG standards for the bicycle industry.

Mini Trade Show

Ora Engineering showed off a titanium e-bike that’s claimed to be the lightest Ti e-bike ever made. As a sustainable way of getting around, the light weight allows for the e-bike to go even farther per charge. Made of scrap titanium that’s been recycled, the e-bike extends its environmental impact as titanium itself is a low carbon footprint metal making it a solid green option.

Mei Ta Industries showcased their new investment cast aluminum frame lugs as part of their diversification from automotive parts. The manufacture of bike parts is a new way for the company to promote more green transportation.

Nouvo, a bell and bottle cage manufacturer, showcased a new bottle cage made from discarded fishing nets that are a major pollutant problem in our oceans. The old nets are being removed and recycled into new plastic bottle cages. The company also is working towards reducing their CO2 emissions by 42% over the next ten years.

Carbon fibre is a material that has traditionally been tough to recycle, but Complam is an innovative company that forms recycled carbon fibre into pellets that is used by other companies to make thermoplastic injection moulded items such as pedals, chain ring spiders or saddle bases. In this way they are giving used carbon fibre a new home.

Old fishing nets are also finding a new home with Hwasahi International that is making sunglasses from the used nets. They are also using biobased plastic from coffee grounds to make the plastic frames for another sunglass model. The advantage of biobased plastics is that they have 45% less of a CO2 footprint.

Finally Wellgo was showing a pedal made of thermoplastic reinforced with recycled carbon fibre material. A first in their line of products that uses carbon that’s recycled from old bicycle frames.