May 23, 2024 - TQ Group began in 1994 in a lovely part of rural Bavaria, just west of Munich, in a region urrounded by lakes. From a storage unit in a barn, founders Detlef Schneider and Rüdiger Stahl began working with electronic components and embedded systems.

From those humble beginnings, TQ has grown into a global player, developing electronic systems for multiple industries including aviation, robotics, automation, medical and now e-mobility with their innovative HPR50 e-drive system.

The two founders were born and raised in the area and wanted to maintain a German, family-run business model. This included creating jobs for local residents, as well as investing in and maintaining the community.

Today, TQ’s Global HQ has taken over the entire sprawling farm site where they started back in 1994, and they’ve since added five other facilities within the same region of Inning am Ammersee and Seefeld.

TQ, which stands for Technology in Quality, has remained a privately owned company, a move which has proven to be an important part of their success. Without having to answer to shareholders, or fast-track products to market, TQ has the luxury of allowing their products to develop organically, staying true to their company values.

Their business model has also proven to be somewhat immune to both major global impacts and extreme shifts in the economy. During the Covid-19 pandemic, TQ’s steady growth in their workforce levelled off but did not decline.

TQ also has a proven track record in motor design with robotics manufacturing, as well as in the service and surgical tools involved with open heart surgery. The company is also involved in prosthetics and the aerospace industry. We’re even told that one of their robots is a dancing sensation on YouTube!

Applying their motor technology to e-bikes seemed a natural pathway; TQ first embarked on its e-bike journey in 2008, and they developed an e-drive division four years later in 2012. The success of their patented harmonic pin-ring technology, initially created for the aerospace sector, was a natural fit for e-bike applications.

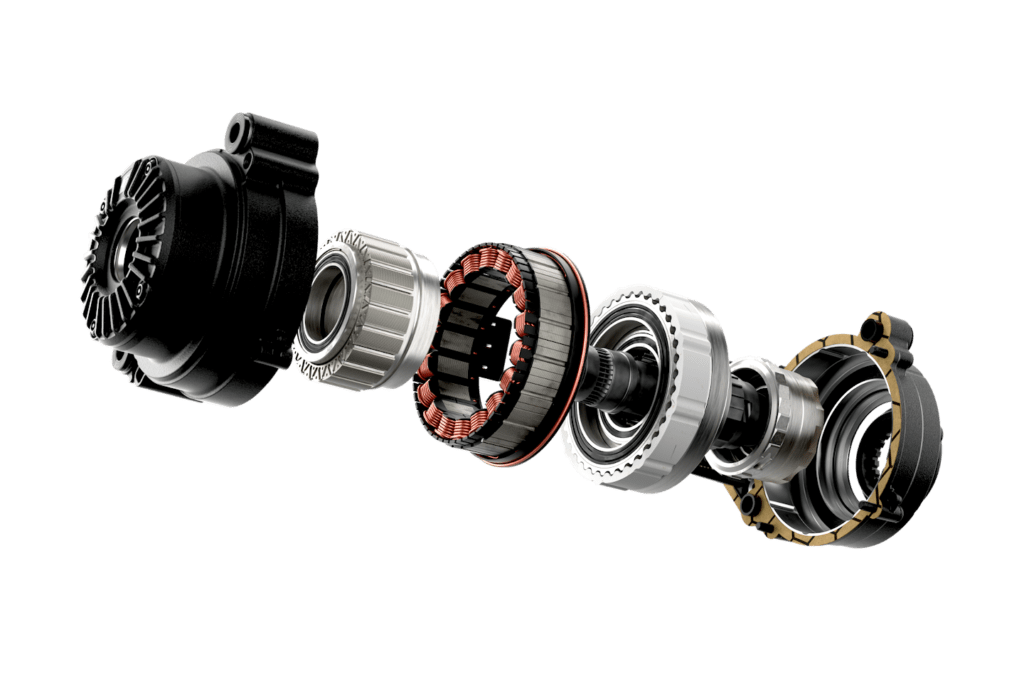

The novel harmonic pin-ring concept does away with cogs, belts and planetary gears in favour of a more refined system. The advanced system includes an elliptical wave generator and two gears — internal and external — which sit on a central axis and are connected by a flexible pin-ring transmitter.

The unique e-drive system can achieve the required reduction between the rider’s pedalling revolutions and the motor in just one step, with a reduction ratio that is about a third of other systems, which need several steps. The compact, lightweight and quiet system also provides one of the highest torque-to-power densities on the market.

TQ’s first e-bike motor boasted 120Nm of torque, which dwarfed most of the other systems. The company’s research team got to work on refining things and in 2018, a partnership developed with Trek that led TQ on a new pathway. In 2022, they released the HPR50, a more naturally intuitive motor and e-drive system that debuted on Trek’s Fuel EXe electric mountain bike that was launched in the summer of that year.

With 50Nm of torque and 300 watts of peak power, the new lightweight motor (1,850g) and compact drive system delivered a very natural ride feeling. The new system features a Q factor of only 135mm, which allows for the same natural and efficient feel on the pedals as analog bikes.

The HPR50 was engineered and produced in a building not far from the company headquarters. TQ landed in this location five years ago when the tenants pulled out, allowing the company to continue growing within their hometown. The workforce has morphed from 60 employees three years ago to over 200 people, in part due to the success of their new e-bike motor division.

The new location houses the engineering and production divisions together in the same building, a move that created a positive and productive environment for developing the HPR50. Communication between each sector is ongoing, and with the research and development division nearby, any input or modifications can be executed quickly and efficiently.

“We are all avid cyclists. We can ride, develop and test our product all in-house — we’re both tech nerds and bike enthusiasts,” explains Anna Vodickova, TQ’s Product Marketing Manager.

TQ’s business model also allows production levels of the HPR50 to remain high, while the inventory of in-house parts is low, because most of the system’s components come from one of its own nearby facilities. The single assembly line utilizes both humans and robots with the former handling the more technical aspects of the build, while the robots perform the more mundane, repetitive jobs. In fact, even the robots are made in-house.

To ensure the highest of standards, once the assembly of each HPR50 unit is complete, it’s placed in a machine that runs through its parameters and system functions. This process is followed by a more rigorous set of tests to ensure that each motor meets TQ’s top-grade production standards.

The result is that the HPR50 is 100% German-made, and TQ has complete control over all the parts and assembly needed to create the motor and drive system.

The system’s compact 360-watt and lightweight battery (1,830g) was specifically developed for the HPR50 drive unit for maximum efficiency. Integrated seamlessly into the downtube, it can be augmented by an optional 160Wh range extender battery, which is the size of a 500ml water bottle and can fit into any standard bottle cage.

The minimalistic bar-mounted ring-sized mode assist remote is almost imperceptible as well.

The HPR50 App is used to customize the motor’s parameters and access support centre communications. The system is also compatible with other computer units in the marketplace to accommodate additional data-savvy riders.

The complete package weighs just 3,900 grams, and it’s claimed to be the lightest e-bike drive system in its category.

“Our philosophy is to be very stealth, to be about the rider and the bike… not the system. It’s not about the numbers, and all about the feel. With TQ it’s more like having a Bike+, not an e-bike,” adds Vodickova.

Close to a dozen more bike companies have come on board, including top-level players like Scott, BMC and Pinarello.

As e-bikes continue to grow worldwide, TQ is well poised to continue on its current trajectory by maintaining and growing their diverse range of products with quality and innovation leading the charge.

Coming from a company with roots in the aerospace industry, it looks like the sky’s the limit.

For more information on the TQ Group click here.

This article first appeared in our eBikes Spring 2024 edition here.